Drawing

We are able to ‘form’ parts from metal sheet as shown in the photo. Not only does round shape can be drawn, but also square and irregular shapes. As we have the equipment and machineries for press, cutting, annealing, barrel polishing, degreasing etc., we are able to carry out all the processes in-house.

Shaving

The cutting edge of the pressed product can be finished to an almost-sheared surface. This technique can be applied to part’s outer shape and holes.

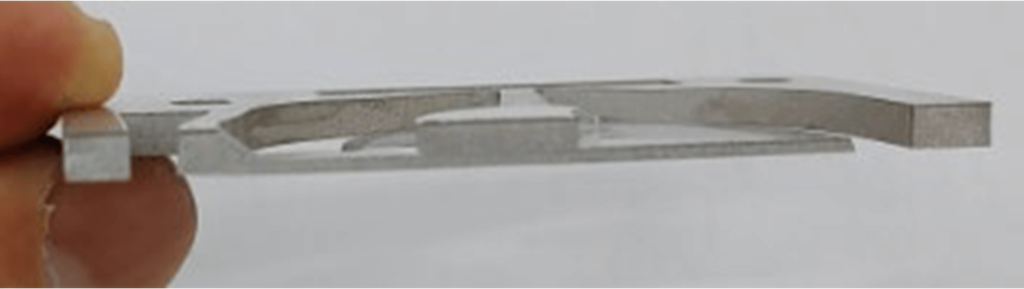

Coining

Depending on the raw material, the aluminum material t3.0mm can be crushed up to about 65% of the plate thickness. If it is iron material, it can be crushed up to about 50% of the plate thickness.

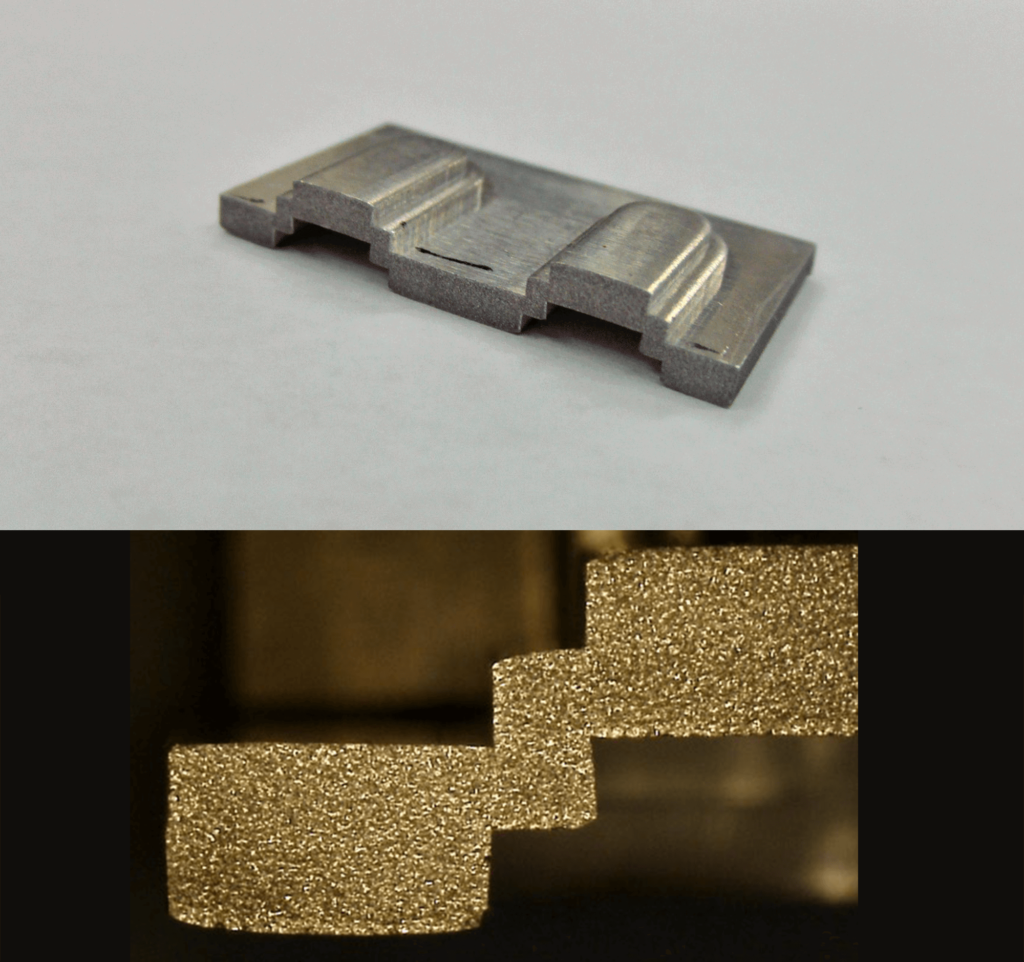

Half piercing

Half piercing is the process of removing about half the thickness of the plate. Using this technique, a two-step shape can be made. We are also able to adjust the tooling in such a way that prevent occurrence of cracks on part, and at the same time, leaving sufficient thickness where it is pressed to become thin. Thus, know-how is required. The below is an example of overcoming challenges in using this technique.

Process example

Application: Traveling wave tubes for artificial satellites and defense-related communication

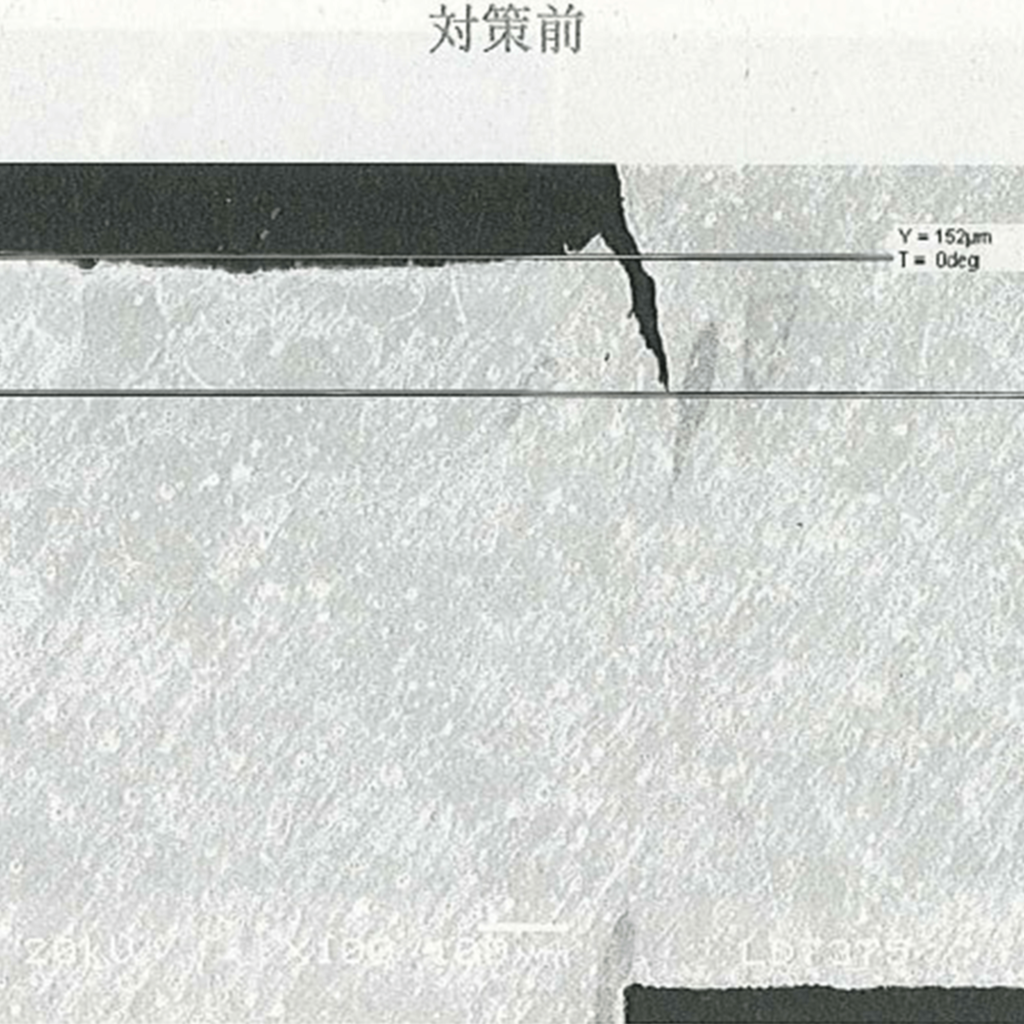

Problem

As it is a vacuum tube part, a crack at the base would result in leakage and be considered defective (NG).

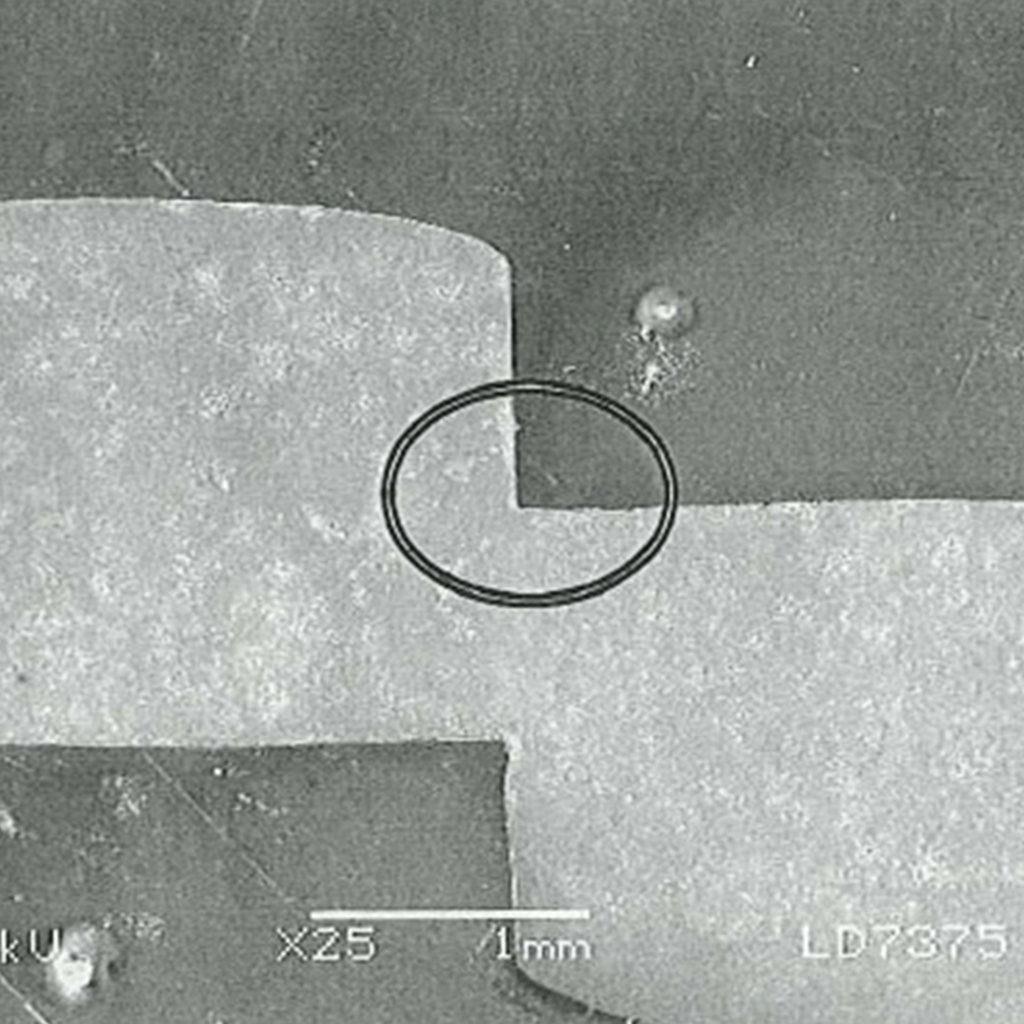

Solution

After several adjustments of tooling clearance, we were able to find the optimum clearance to prevent occurrence of cracks.

Customer’s acceptance

Contact

Please feel free to contact us using the Inquiry Form.