Quality Assurance System

We have established a Quality Assurance System that meets the Quality requirements of our customers:

- High-precision dimensional measurement in μ units using the latest measurement equipment with image analysis and optical system

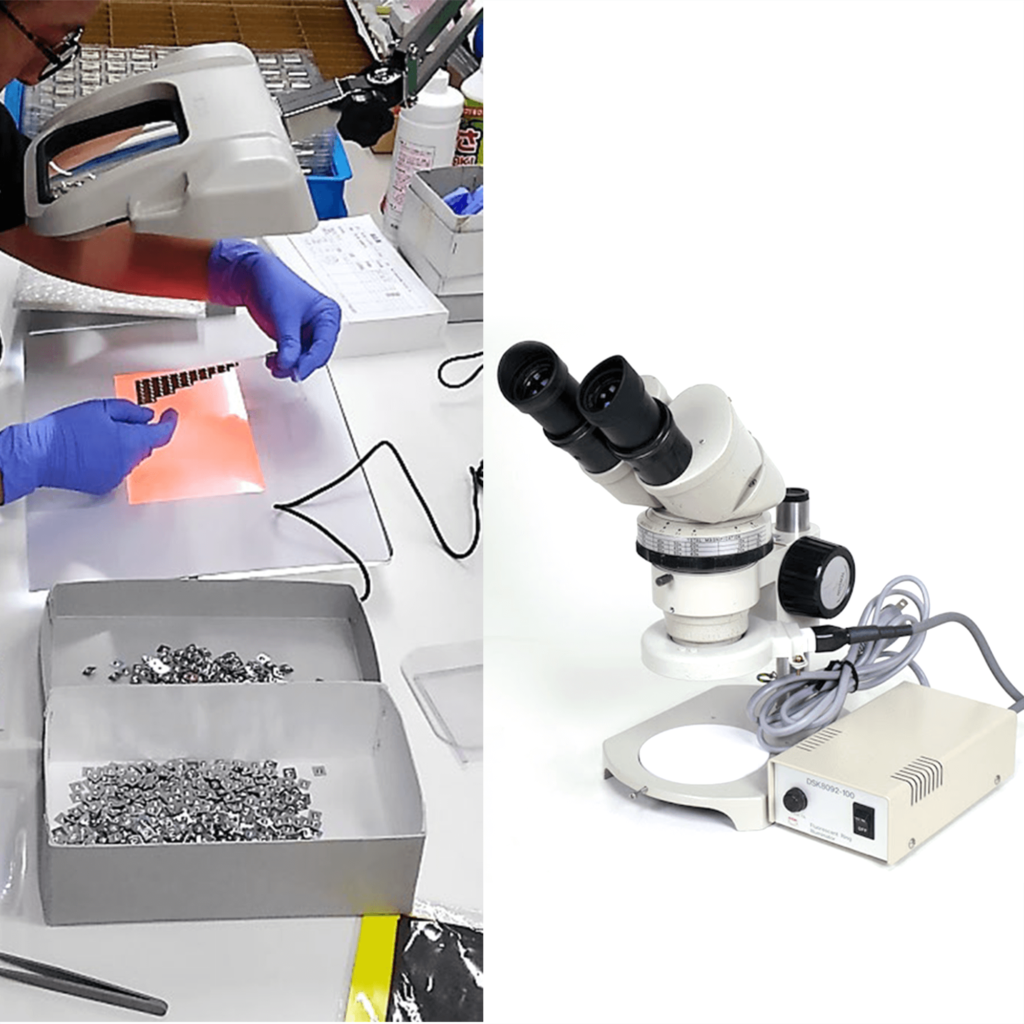

- Visual inspection using high-magnification digital microscope, microscope, or magnifier

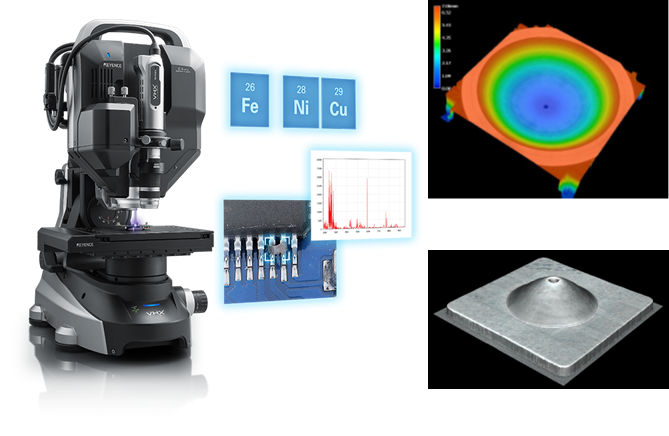

- 3D shape analysis with high-resolution image capture and laser elemental analysis

- Packing condition that meets customer’s request and its intended use

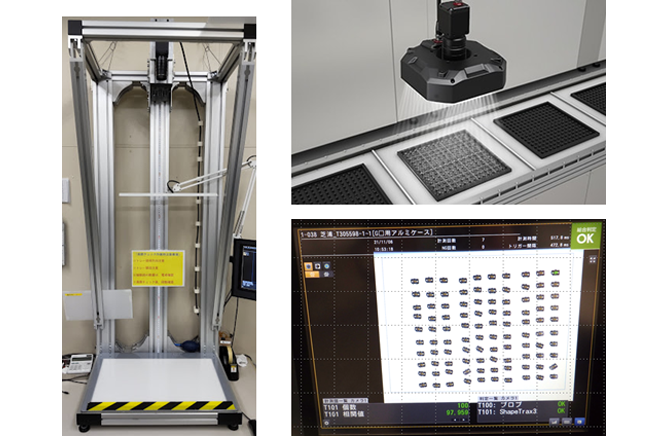

- Appearance judgment and quantity confirmation using high-resolution camera and image sensor

Furthermore, we support various tests and analytical investigations:

- Material hardness measurement (Vickers)

- Load measurement

- Environmental substance analysis, RoHS and REACH compliance

- ChemSHERPA

In-line Check, System & Quality Improvement, Horizontal Application

Our Quality Assurance Department checks the quality of parts such as dimensions and appearance at the time of production, and feedback to Production when there is any issue. Production resumes after tooling maintenance and dimension adjustment. In addition, improvement measures are applied accordingly to parts having similar processes. We strive to provide high-quality parts to meet customer’s needs and satisfaction.

Measuring Equipment

-1-1024x576.jpg)

(Image Measure)

-1-1024x576.jpg)

(NEXIV)

Visual Inspection

Analysis & Image Processing Equipment

(VHX-8000+EA-300)

(KEYENCE CV-X490F+64MP Camera)

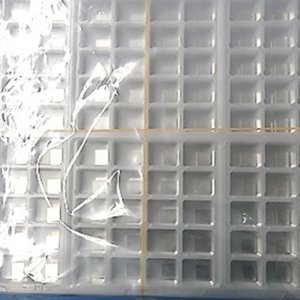

Packing

Tray Packing

Tray can be customized using different type of material and design

Tape and Reel Packing

Reel and carrier tape can be customized based on customer’s requirement in terms of material type, lot size, pocket shape and design etc.

Contact

Please feel free to contact us using the Inquiry Form.